Versatile Design Options with UHPC Wall Panels: Innovation in Modern Architecture

Industry Background and Market Demand

The construction industry is increasingly prioritizing materials that combine durability, aesthetic flexibility, and sustainability. Ultra-High Performance Concrete (UHPC) wall panels have emerged as a leading solution, addressing the demand for resilient, lightweight, and visually adaptable building components. With urbanization accelerating and architectural trends favoring sleek, high-performance designs, UHPC offers structural efficiency without compromising on creative freedom.

Market demand is particularly strong in commercial, institutional, and high-end residential projects where long-term performance and design differentiation are critical. Developers and architects seek materials that reduce maintenance costs while enabling complex geometries—requirements that traditional concrete or precast panels struggle to meet.

Understanding UHPC: Core Properties and Technology

UHPC is a cementitious composite characterized by its exceptional compressive strength (150–250 MPa) and ductility, achieved through a dense microstructure and fiber reinforcement. Unlike conventional concrete, UHPC incorporates fine-grained materials such as silica fume and quartz flour, along with steel or polymer fibers, eliminating the need for traditional rebar in many applications.

Key advantages include:

- High tensile strength (7–15 MPa), reducing cracking and improving longevity.

- Ultra-low permeability, enhancing resistance to corrosion, freeze-thaw cycles, and chemical exposure.

- Thin-section capabilities, enabling slimmer profiles without sacrificing load-bearing capacity.

These properties make UHPC wall panels ideal for façades, cladding, and structural applications where conventional materials would require thicker, heavier sections.

Product Structure and Manufacturing Process

UHPC wall panels are manufactured through a precision-driven process:

1. Material Mixing: A precisely controlled blend of Portland cement, silica fume, fine aggregates, and superplasticizers ensures optimal flowability and strength.

2. Fiber Integration: Dispersed steel or synthetic fibers reinforce the matrix, improving flexural performance.

3. Molding and Curing: Panels are cast in custom molds, often with textured or patterned surfaces, and cured under controlled temperature and humidity to achieve maximum density.

4. Post-Treatment: Optional heat treatment or surface coatings (e.g., hydrophobic sealants) can further enhance durability.

The result is a panel that can be as thin as 20–30 mm while outperforming traditional precast concrete in both mechanical and aesthetic properties.

Critical Factors Influencing Performance

Several variables determine the quality of UHPC wall panels:

- Fiber Type and Distribution: Uniform dispersion is crucial to prevent weak spots.

- Curing Conditions: Improper curing can lead to microcracks, reducing long-term durability.

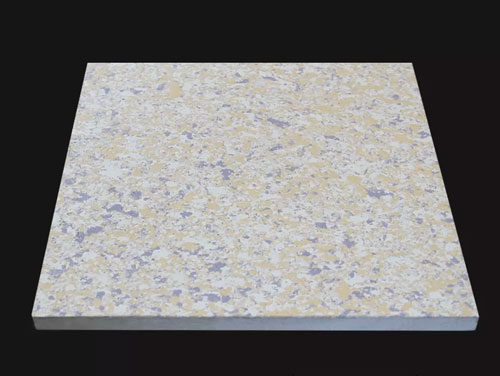

- Surface Finish: Architectural panels require meticulous mold design to achieve desired textures.

- Admixture Ratios: Excess superplasticizers may weaken the matrix if not balanced correctly.

Supplier Selection and Supply Chain Considerations

When sourcing UHPC panels, key criteria include:

- Technical Expertise: Suppliers should demonstrate proficiency in mix design and structural engineering.

- Customization Capabilities: The ability to produce bespoke shapes, textures, and colors is essential for high-end projects.

- Certifications: Compliance with ASTM C1856 or EN 206-1 ensures material consistency.

- Logistical Support: Given UHPC’s sensitivity to handling, suppliers must provide secure packaging and transportation solutions.

Leading manufacturers often collaborate closely with architects to optimize panel dimensions, connection systems, and installation protocols.

Common Challenges and Industry Pain Points

Despite its advantages, UHPC adoption faces hurdles:

- High Initial Costs: Raw materials and specialized labor increase upfront expenses, though lifecycle savings offset this.

- Limited Awareness: Some specifiers remain unfamiliar with UHPC’s full potential.

- Supply Chain Gaps: Regional availability of high-quality UHPC producers can be inconsistent.

Applications and Case Studies

UHPC wall panels excel in diverse scenarios:

- Façade Systems: The Salesforce Transit Center in San Francisco features UHPC cladding for its durability and sleek finish.

- Modular Construction: Prefabricated UHPC panels accelerate timelines for hospitals and data centers.

- Historic Renovations: Thin UHPC overlays restore aging structures without adding significant weight.

Trends and Future Outlook

Innovations in UHPC focus on:

- Sustainability: Incorporating recycled materials and reducing carbon-intensive components.

- Digital Fabrication: 3D-printed UHPC enables unprecedented geometric complexity.

- Hybrid Systems: Combining UHPC with carbon fiber or glass fiber for even lighter solutions.

As R&D continues, UHPC is poised to redefine architectural possibilities, merging engineering rigor with artistic expression.

---

FAQ

Q: How does UHPC compare to traditional precast concrete?

A: UHPC offers superior strength, thinner profiles, and greater design flexibility due to its fiber-reinforced matrix.

Q: Is UHPC suitable for seismic zones?

A: Yes, its high ductility and crack resistance make it ideal for earthquake-prone regions.

Q: What maintenance do UHPC panels require?

A: Minimal upkeep is needed; occasional cleaning and inspections for surface coatings suffice.

Q: Can UHPC be colored or textured?

A: Yes, pigments and custom molds allow for a wide range of finishes, from polished to rugged.

By integrating UHPC wall panels into modern construction, stakeholders can achieve unparalleled performance and design versatility.

Questo sito utilizza i cookie per assicurarti la migliore esperienza sul nostro sito.

Commento

(0)